Braided hoses can withstand pressures from 250 PSI to 6500 PSI. The size and type of hose affect its pressure resistance. Pressure ratings also depend on the material, diameter, and how the user intends to use it. The table below shows how these factors affect hose performance:

| Aspect | Influence on Pressure Ratings |

|---|---|

| Material | Steel wire can withstand high pressure. |

| Diameter | The larger the diameter, the greater the pressure the hose can withstand. |

| Application | Domestic or industrial applications will affect the required pressure. |

Choosing the right hose ensures safe and reliable system operation. GONGGONG is a trusted brand. They use high-quality materials to create robust and durable braided hose solutions.

Key Takeaways

- Braided hoses can withstand pressures from 250 PSI to 6500 PSI. Specific values depend on the hose’s size and material. Choosing the right hose ensures safe and efficient operation. – Stainless steel braided hoses will not rust and can withstand high pressure and high temperatures. – Regularly inspecting the hose and ensuring proper installation can prevent problems and protect personnel. – GONGGONG hoses meet international standards and are robust and durable.

Braided Hose Pressure Ratings

Braided Hose Common Pressure Ranges

Braided hoses can withstand a variety of pressures. Their pressure rating depends on the hose’s size, material, and manufacturing process. Most braided hoses operate at pressures ranging from 250 PSI to 6500 PSI. Some hydraulic hoses have even higher pressure ratings. The table below lists the maximum working pressure and burst pressure of hoses of different sizes:

| Inside Diameter (in.) | Maximum Working Pressure (psi) | Burst Pressure (psi) |

|---|---|---|

| 1/4 | 450, 3000, 4000 | 12000, 16000 |

| 3/8 | 400, 2400, 3300 | 9600, 14000 |

| 1/2 | 400, 2400, 3200 | 9600, 12800 |

| 3/4 | 220, 1100, 1650 | 4430, 6696 |

| 1 | 190, 1000, 1400 | 4187, 5837 |

Manufacturers consider a safety factor when setting pressure ratings. For example, if a hydraulic hose has a working pressure of 3,000 PSI, its burst pressure should be at least 12,000 PSI. This 4:1 safety factor helps prevent sudden pressure spikes or hose wear, thus ensuring personnel safety.

GONGGONG conducts rigorous quality testing on every braided hose to ensure compliance with all standards. The company tests all materials and follows international standards for drinking water and hydraulic hose systems. This ensures that every product can withstand high pressure and is durable.

Factors That Affect Pressure

Many factors affect the rated pressure of braided hoses. Among the most important are:

- Diameter: Smaller hoses can withstand higher pressures. For example, a 3/16-inch hydraulic hose can withstand pressures up to 3,250 PSI, while a 2-inch hose may only withstand 580 PSI. Larger diameters result in lower pressure.

- Number of Reinforcing Layers: The number of reinforcing layers inside the hose is crucial. A single reinforcing layer is suitable for low or medium pressure environments. Two-layer hoses can withstand medium or high pressures, sometimes even up to 6,000 PSI. Multi-layer hoses are better suited for ultra-high pressure environments, typically exceeding 10,000 PSI.

- Construction Type: Braided reinforcement makes the hose stronger and more durable. Spiral reinforcement is prone to twisting and breaking under pressure. Braided hoses are better suited for high-pressure operations.

- End Fittings: The type and quality of the end fittings are also important. High-quality fittings help prevent leaks and bursts.

Tip:Always check the manufacturer’s pressure rating before using a hydraulic hose. Using a hose beyond its rated pressure can cause it to rupture, leak, be damaged, or even cause personal injury.

Exceeding the rated pressure of a braided hose can have serious consequences. The hose may rupture, causing economic losses and flooding. If a hydraulic hose bursts during operation, it can cause personal injury. High pressure can also reduce hose strength and lead to premature failure.

GONGGONG ensures that every braided hose meets or exceeds industry standards. The company uses high-quality materials and advanced processes to manufacture hoses, providing safe and reliable hydraulic hose solutions for a wide range of applications.

Stainless Steel Braided Hose Features

Braided Hose Material Benefits

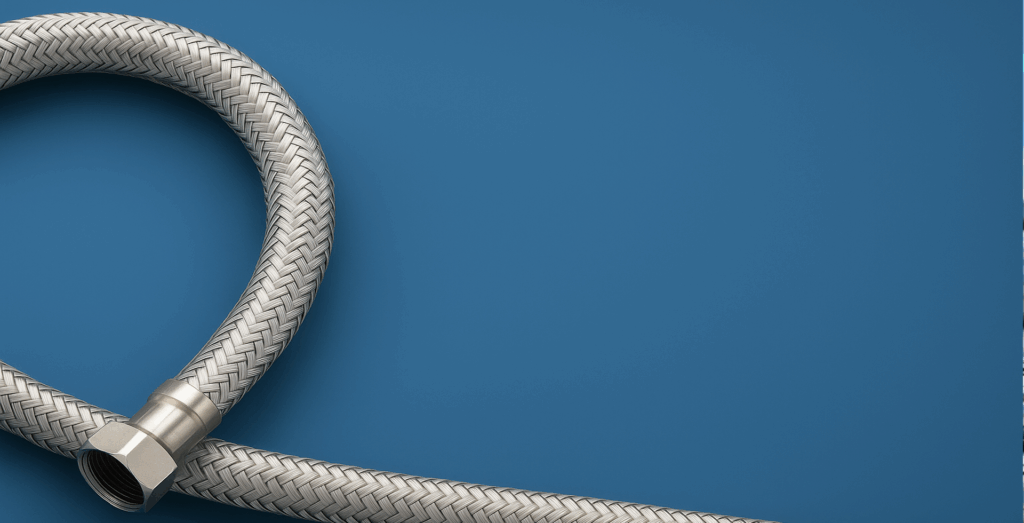

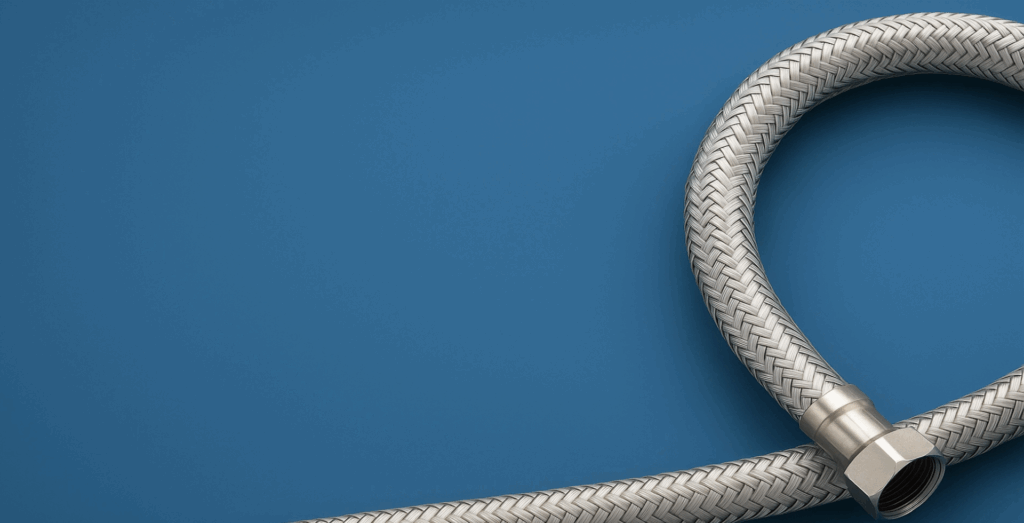

Stainless steel braided hoses offer numerous advantages. Their outer layer is made of stainless steel, effectively preventing scratches, cuts, and rust. Therefore, the hose is durable even in harsh environments. The special braiding process makes the hose strong and durable, able to withstand high pressure while maintaining good bending performance.

- More effective protection against scratches and rust

- Maintains flexibility while providing excellent protection

- Designed for harsh environments

- The braided structure makes it extremely robust

- Capable of withstanding high pressure and high temperatures

All GONGGONG hoses are made of top-grade stainless steel. Many hoses also have an internal PTFE lining. These linings make the hoses more flexible and robust, able to withstand high temperatures and strong chemical corrosion. This helps extend the hose’s lifespan and ensures its safety. The PTFE lining keeps the inside clean and prevents cracking under pressure.

Note: Stainless steel braided hoses are ideal for harsh working environments. They can withstand high pressure and high temperatures. Therefore, they are used in many industries.

Braided Hose Applications and Durability

Stainless steel braided hoses have a wide range of applications, including hot and cold water piping, bathrooms, and factories. GONGGONG supplies these hoses for critical applications such as kitchens, bathrooms, and workplaces.

- Food & Beverage: For conveying juices, milk, beer, and alcoholic beverages

- Pharmaceuticals: For conveying hot, clean liquids

- Beauty & Personal Care: For conveying creams and liquids containing alcohol

- Chemicals: For conveying corrosive liquids

These hoses can withstand high pressure and high temperatures. Thick walls make it durable. Regularly inspecting the hose for damage, ensuring joints are tight, and guaranteeing proper installation will ensure good operation. Never excessively twist or bend the hose. Replace it immediately if any damage is found.

Stainless steel braided hoses remain robust and durable in many applications. Their robust construction and resistance to chemical corrosion make them ideal for homes and businesses.

Choosing the Right Braided Hose

Matching Pressure to Application

You need to understand the pressure and flow rate required for your application. Each application has its unique requirements. Kitchen sink hoses require much lower pressures than factory hoses. The following table lists factors you should consider:

| Factor | Description |

|---|---|

| Flow Requirements | The required volume of liquid or gas will affect the hose size. This helps avoid pressure problems. |

| Operating Pressure | Smaller hose sizes are better suited for high-pressure environments. Larger hose sizes are better suited for low-pressure environments. |

| Application Environment | The environment in which the hose will be used is critical. Consider the size of the space, temperature, and whether the chemicals are safe for the hose. |

| Industry Standards | Some industries, such as HVAC or chemical operations, have specific regulations regarding hose sizes. |

Choosing the right pressure-resistant hose ensures safety. The table below lists potential problems caused by insufficient hose strength:

| Risk Type | Description |

|---|---|

| Hose Failure | The hose can leak, burst, or break badly. |

| Production Downtime | If the hose fails, work may stop for a long time. |

| Environmental Contamination | Leaks can let bad stuff get into the air or water. |

| Injury or Death | A burst hose can hurt or even kill someone. |

Tip: Always use a hose suitable for its intended use and check its rated pressure before installation.

Braided Hose Safety and Certification

When selecting braided hoses, safety is paramount. Always consult the manufacturer’s instructions and check safety labels. GONGGONG hoses meet stringent international standards for water and hydraulic systems. Review test results and safety documentation to ensure the hose can withstand pressure, especially under high temperatures or significant pressure variations.

Some important guidelines include:

- ISO standards, such as ISO 18752, classify hoses according to their pressure resistance.

- DIN standards are even stricter and suitable for heavy-duty operations. DIN standards impose higher pressure resistance tests on hoses.

Regularly inspect and replace hoses to ensure safety. Here are some effective steps:

- Develop a hose inspection plan to prevent hose failure.

- Use appropriate tools to connect hoses.

- Ensure that hoses and fittings match the operational requirements.

- Use the correct model when replacing hoses.

- Record the time of each hose replacement for future reference.

Hose used in critical locations or high-pressure environments require more frequent inspections. High temperatures or corrosive chemicals accelerate hose wear. Proper hose maintenance helps extend their lifespan and ensures everyone’s safety.

Understanding the pressure rating of braided hoses helps ensure safety. These ratings are crucial for protecting people and equipment. The material and manufacturing process of the hose affect its pressure resistance. Temperature and movement also affect hose performance.

Choosing a certified hose like GONGGONG ensures safety and high quality. For best results, users should choose a hose with a pressure rating higher than their actual needs. Users should regularly check hoses for leaks or damage. Using the correct hose fittings and the appropriate fluid is essential. When storing hoses, avoid excessive bending or placing heavy objects on them.

FAQ

What is the difference between braided hoses and regular hoses?

Braided hoses use metal or synthetic fiber braids for added strength. This design allows the hose to withstand higher pressures and is more resistant to kinking than regular rubber or plastic hoses.

Can braided hoses be used for hot and cold water?

Yes. Braided hoses are suitable for both hot and cold water. The stainless steel and PTFE lining protects the hose from both high and low temperatures, making it versatile and safe.

How often should braided hoses be replaced?

Most experts recommend checking hoses annually. Replace the hose if signs of wear, leakage, or rust appear. Regular inspections help prevent sudden hose failure.

What certifications should a high-quality braided hose have?

High-quality braided hoses should meet standards such as ISO 18752 or DIN. These certifications indicate that the hose has passed pressure, safety, and durability tests.

Why choose GONGGONG braided hoses?

GONGGONG uses premium materials and undergoes rigorous quality testing. Its hoses meet global safety and performance standards. Numerous industries trust GONGGONG and choose its reliable and durable hose solutions.