Choosing the right braided hoses can make machines safer and work better in many jobs. The table below lists the most common types and what they are used for:

| Type of Braided Hose | Primary Uses |

|---|---|

| Steel Braided Hoses | Used in factories, chemical pipes, hydraulic systems, and moving steam |

| HVAC Systems | Joins compressors and condensers, stops shaking, lowers stress on parts |

| Medical Equipment | Moves clean fluids and gases in surgery and testing tools |

| Construction Machinery | Runs hydraulic systems in big machines, works with high pressure |

If you pick the wrong braided hose, you might have these problems:

- Cracks and leaks from getting old or worn out

- Rust on connectors and fittings

- Bursting from too much water pressure

Knowing about braided hoses helps people make safer and smarter choices.

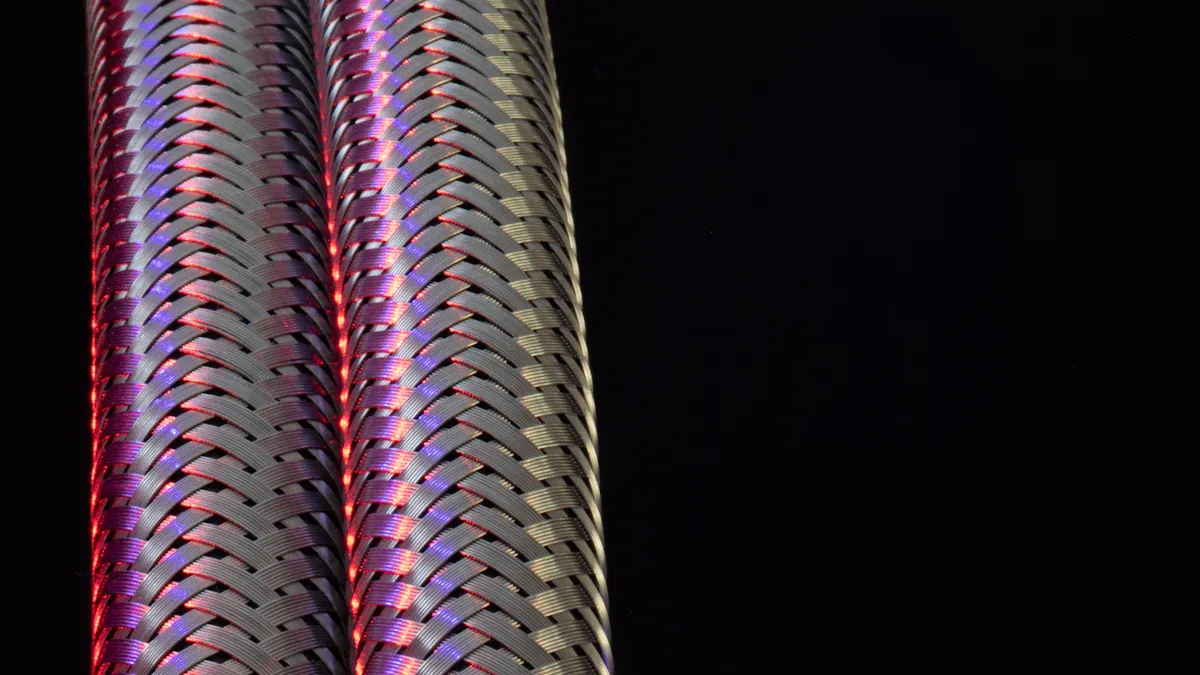

What Is a Braided Hose?

Structure and Function

A braided hose is a bendable tube. It has a strong outside layer made from woven metal or synthetic fibers. This design follows rules set by groups like ISO 10380. These rules tell companies how to make and test braided hoses, especially metal ones.

| Standard | Description |

|---|---|

| ISO 10380 | Rules for making braided hoses, mostly for metal hoses. |

Braided hoses have some big benefits over regular hoses. They can handle high pressure without breaking or swelling. The braided layer keeps the inside tube safe from cuts and scrapes. This helps the hose last longer, even in rough places. Regular hoses can bend too much or get holes more easily. They do not work well with high pressure and wear out faster.

Because of these good features, braided hoses are used where safety and strength are important.

Common Applications

Braided hoses are used in many jobs because they are tough and last long. Some common uses are:

- Plumbing: Connects water to sinks, toilets, and other things.

- HVAC: Moves water, antifreeze, or refrigerant, and deals with changes in heat and pressure.

- Cars and machines: Carries fuel, oil, brake fluid, and coolant, and stands up to heat and shaking.

- Factories: Moves chemicals, water, steam, or gases in machines that work all day.

- Farms: Used in watering and cleaning tools for animals, and works well outside.

- Boats: Sends fuel and cools engines in ships.

- Fire safety: Connects water pipes to sprinklers and works under high pressure.

Other places like planes, oil and gas sites, and chemical plants also use braided hoses. These hoses help keep systems safe and working well in many different places.

Braided Hose Materials

Stainless Steel Braided Hoses

Stainless steel braided hoses use a tough metal weave. This weave protects the inside tube. The design makes them strong and long-lasting. The metal braid does not rust. It works well in rough places. Many industries pick these hoses for high pressure and heat.

Note:

SS braided hoses work in very cold and very hot places. They can handle up to 1500°F. They also work with full vacuum and high pressure.

Key Advantages:

- They do not rust or wear out easily.

- They last a long time, even in hard jobs.

- They bend easily, so you can install them anywhere.

Best Applications:

- Used in cars where it gets hot and pressure is high.

- Used in chemical plants for safety.

- Used in plumbing where you need strong hoses.

Typical Ratings:

- Handles full vacuum and high pressure.

- Works from -320°F to 1500°F.

Table: Common Braided Hose Types and Material Advantages

| Hose Type | Material Type | Advantages |

|---|---|---|

| Single Braided Hose | Reinforced inner hose | Lightweight, flexible, resistant to chemical breakdowns, suitable for hydraulic systems and fuel delivery. |

| Double Braided Hose | High-tensile stainless steel | Superior performance, greater pressure capacity, increased flexibility, and durability. |

| Close-Pitch Braided | Reinforced strands | Improved flexibility, reduced abrasion, increased cycle life, and lower maintenance costs. |

| Open-Pitch Braided | Advanced synthetic core | Superior chemical resistance, high-temperature function, minimal bends for increased flow rate. |

| Strip-Wound Hose | Stripped metal | Strong support, resistance to vibration and corrosion, easy installation, and suitable for HVAC systems. |

SS braided hoses cost more than other types. But they last longer and work better. This saves money over time. They are best when safety and strength matter most.

PTFE Braided Hoses

PTFE braided hoses have a core made from a special plastic. This plastic is called polytetrafluoroethylene. The core is wrapped with a stainless steel braid. This makes the hose stronger. PTFE braided hoses are good when chemicals might hurt other hoses.

Tip:

PTFE braided hoses do not get damaged by most acids, alcohols, soaps, or solvents. This is why labs and chemical plants use them.

Main Advantages:

- They do not get hurt by chemicals.

- They work in hot and cold places.

- The inside is smooth, so it is easy to clean.

Best Applications:

- Used in factories to move chemicals.

- Used in food and drink plants to keep things clean.

- Used in medical tools to move pure fluids.

Chemical Compatibility Table

| Chemical Type | PTFE Resistance |

|---|---|

| Acids | Excellent |

| Alcohols | Excellent |

| Detergents | Excellent |

| Solvents | Excellent |

PTFE braided hoses cost more than rubber hoses. But they last longer with harsh chemicals and heat. This makes them a good choice for many jobs.

Rubber Braided Hoses

Rubber braided hoses have a soft rubber or plastic core. A woven mesh covers the hose. The mesh is made from strong fibers or metal. This makes the hose bendy and tough. It bends easily but does not break or get holes.

Performance Comparison Table

| Characteristic | Braided Hoses | Standard Hoses |

|---|---|---|

| Flexibility | Less flexible due to reinforced construction, but smaller bend radius for maneuverability | Greater flexibility, easier to handle and reposition |

| Durability | Highly resistant to wear and punctures due to woven mesh reinforcement | Generally less durable than braided hoses |

Key Features:

- Bends well in small spaces.

- Does not wear out or get holes easily.

- Protects from outside scrapes.

Best Applications:

- Used in farm and building machines.

- Used in cars for fuel, oil, and coolant.

- Used in plumbing and water lines.

Rubber braided hoses cost less than ss braided hoses or PTFE hoses. People use them for simple jobs. They may not last as long in tough places with heat or chemicals.

Note:

The price of braided hoses depends on what they are made of, how they are built, and what job they do. Car makers pay more for ss braided hoses to keep cars safe. People use rubber braided hoses in homes to save money.

Types of Braided Hoses

Single Braided

Single braided hoses have one braid layer around the tube. This makes them strong and lets them bend easily. The braid helps stop the hose from swelling too much. These hoses work best for jobs with low or medium pressure.

Key Features:

- One braid layer gives basic support.

- They are light and simple to use.

- They bend well in small spaces.

Ideal Uses:

- Used in home plumbing.

- Good for small machines.

- Used for water lines.

- Works in small engines.

Single braided hoses cost less than other types. They are best when you do not need high pressure. Many people use them at home or in small machines.

Double Braided

Double braided hoses have two braid layers. The extra braid makes them much stronger. These hoses can handle more pressure than single braided hoses.

Double braided hoses work well with higher pressure than single braided hoses.

The two braids make them strong, so they are good for big machines and tough jobs.

Key Features:

- Two braid layers give extra strength.

- They do not burst easily.

- They are good for hard jobs.

Ideal Uses:

- Used in hydraulic systems.

- Used for steam lines.

- Good for oil and gas.

- Used in big machines.

Double braided hoses last longer in tough jobs. They help keep people and machines safe when pressure is high.

Close-Pitch

Close-pitch braided hoses use tightly packed strands. The tight braid lets the hose bend without kinking. This also helps protect the hose from damage.

Key Features:

- Tight braid lets it bend smoothly.

- Lasts a long time.

- Less likely to get damaged.

Ideal Uses:

- Used in robots and moving machines.

- Good for parts that move a lot.

- Works well where hoses bend often.

Close-pitch hoses are great for places where the hose moves a lot. The tight braid keeps the hose safe and strong.

Open-Pitch

Open-pitch braided hoses have wider gaps in the braid. This makes the hose lighter and easy to bend. You can also see inside the hose for checks.

Key Features:

- Wide braid makes it light.

- Bends easily.

- Easy to look inside.

Ideal Uses:

| Application Type | Description |

|---|---|

| Sanitary transfer | Good for moving clean materials |

| Food, flavors, and syrups | Used for food and drinks |

| Solvent transfer | Moves solvents safely |

| Drain and sample lines | Used for draining and samples |

| Semi-transparent sight gauges | Lets you see inside the hose |

| Corrosive environments | Works with harsh chemicals |

Open-pitch braided hoses come in many sizes and strengths. The table below shows some common sizes and how they perform:

| Inner Diameter (mm) | Outer Diameter (mm) | Wall Thickness (mm) | Minimum Bend Radius (mm) | Maximum Working Pressure (Psi) | Vacuum Rating (inHg) |

|---|---|---|---|---|---|

| 19.05 | 34.93 | 7.94 | 70 | 250 | 29.9 |

| 25.4 | 38.1 | 6.35 | 102 | 250 | 29.9 |

| 31.75 | 47.63 | 7.94 | 114 | 200 | 29.9 |

| 38.1 | 53.98 | 7.94 | 127 | 200 | 29.9 |

| 50.8 | 66.68 | 7.94 | 152 | 150 | 29.9 |

| 63.5 | 85.73 | 11.11 | 305 | 120 | 29.9 |

| 76.2 | 101.6 | 12.7 | 330 | 100 | 29.9 |

Open-pitch braided hoses are used in food plants and labs. They are also good when you need to see the fluid inside. The design helps with harsh chemicals too.

Strip-Wound

Strip-wound braided hoses use metal strips that lock together. These strips wrap around a soft core. This makes the hose very bendy and able to fit in small spots.

- Construction: Strip-wound hoses use metal strips that lock together. Corrugated hoses use one long metal tube.

- Flexibility: The locking strips make strip-wound hoses very bendy. They can go around corners and fit in tight places.

- Cost: Strip-wound hoses usually cost less than corrugated hoses.

- Limitations: These hoses do not handle high pressure or heat. They are not for very tough jobs.

Ideal Uses:

- Used in HVAC to stop shaking.

- Good for dust and fume removal.

- Protects cables in machines.

- Used for low-pressure air and water.

Strip-wound braided hoses are best when you need a cheap and bendy hose. They are not for high pressure jobs.

Many industries must follow rules for braided hoses. Some rules are SAE J517 for cars, ISO 18752 for factories, and FDA 21 CFR 177.1500 for food and medical hoses. These rules help keep people safe and make sure hoses work right.

| Standard Type | Standards | Description |

|---|---|---|

| Automotive | SAE J517, SAE J1404, SAE J2064 | Rules for car and brake hoses |

| Industrial | ISO 18752, ISO 11425, ISO 6806 | Sizes and how rubber hoses should work |

| Food and Medical | FDA 21 CFR 177.1500, USP Class VI, 3-A | Rules for food and medical hoses |

| International | EN 853, JIS K 6339, GB/T 3683 | Rules for hoses used around the world |

Choosing the Right Braided Hose

Application Needs

Picking the right braided hose is important. You need to think about a few things. Each job needs a special kind of hose. Always match the hose to the job for safety.

- Chemical Compatibility: The hose must not get ruined by chemicals.

- Pressure Rating: The hose should handle the highest pressure in the system.

- Temperature Rating: The hose must work in the right temperature range.

- Flexibility and Bend Radius: The hose should bend without breaking.

The table below shows how different needs change which hose you pick:

| Application Need | Hose Type | Material Characteristics |

|---|---|---|

| High-Pressure Systems | Steel Braided Hose | Handles high pressure, good for big machines and oil rigs. |

| Pressure Cycling | Steel Braided Hose | Stays strong when pressure goes up and down a lot. |

| High-Temperature Applications | Steel Braided Hose | Works in very hot places, up to 600°F. |

| Low-Temperature Applications | Synthetic Materials | Polyester or nylon stay bendy in cold weather. |

| Chemical Resistance | Synthetic Braids | Made to stand up to harsh chemicals. |

| Abrasion Resistance | Steel Braided Hose | Does not get damaged easily, good for rough jobs. |

| Environmental Protection | Synthetic Materials | Stays safe outside in sun and rain. |

Steel braided hoses are best for high-pressure jobs. They are safe and last a long time. Synthetic braided hoses are good for chemicals or outdoor use. Always check the hose ratings before you buy.

Fittings and Compatibility

Getting the right fittings matters too. The connector must match the hose and the fluid. Stainless steel connectors are popular. They do not rust and work with high pressure.

- Material compatibility stops bad chemical reactions.

- Connection types are threaded, quick-release, and flanged.

- Connector pressure ratings must be as strong as the hose.

- Industry rules tell you how to connect hoses.

- Chemical plants may use the HG standard. Oil plants may use the SH standard.

- Matching standards keeps connections tight and leak-free.

Braided hydraulic hoses use steel wires woven together. This makes them strong and bendy. They work best in medium-pressure jobs like farm machines. Spiral hydraulic hoses use steel wires wrapped in a spiral. These hoses are stronger for high-pressure jobs like mining. Spiral hoses cost more and do not bend as much. But they last longer when used a lot.

Tip: Always check the hose and fitting standards before you install. This helps stop leaks and keeps everything working safely.

Care and Safety for Braided Hoses

Maintenance Tips

Taking care of braided hoses helps them last longer. It also keeps machines safe. Checking hoses often stops problems and saves money. There are some important things to do:

- Look at hoses often for damage or leaks.

- Clean hoses with the right cleaner for the hose type. Make sure hoses are dry before you put them away.

- Put hoses in the right way so they do not get pulled or twisted.

- Keep hoses in a cool, dry spot. Do not let the sun hit them. Do not bend them too much.

- Check for cracks, leaks, or color changes on a set schedule.

- Watch for fraying, kinks, or other damage every time you check.

- Use soft cleaners so the hose does not rust.

- Store hoses so they do not bend or rub on rough things.

Checking hoses and storing them right stops most problems.

The table below shows how to stop common hose problems:

| Cause of Failure | Prevention Method |

|---|---|

| Pitting Corrosion | Use better alloys like 316L stainless steel. |

| Fatigue | Pick hoses that bend easier to lower stress. |

| Vibration | Put hoses in to shake less and avoid strong vibrations. |

| Pressure Rupture | Use hoses made for the right heat and pressure. Add guides and anchors. |

Safety Precautions

Safety is very important when using braided hoses. Workers should do these things to stay safe:

- Wear safety gear like hard hats, glasses, gloves, and strong shoes.

- Use hose guards and change any that are broken or missing.

- Check hoses often and change any that look worn or damaged.

- Keep hoses off the ground with reels or hangers so no one trips.

- Store hoses in clean, dry places and do not stack them.

- Mark dangerous spots with bright tape.

- Make sure hoses have no pressure before taking them off or fixing them.

- Only use hoses and fittings made for the system’s pressure.

- Test the system after putting in hoses to look for leaks or loose parts.

Keeping floors dry and moving hoses out of the way stops slips and trips.

For important jobs, experts say to change hoses every 5 to 10 years if things are normal. If the job is tough or uses high pressure, change hoses every 3 to 5 years.

Picking the right braided hose means knowing about the different materials and types. The table below shows the main differences:

| Hose Type | Key Features | Best Use Cases |

|---|---|---|

| Rubber | Flexible, chemical resistant | Cars, general fluid transfer |

| Thermoplastic | Lightweight, cost-effective | Food, agriculture |

| Metal | High-pressure, heat resistant | Hydraulic, aerospace |

You should think about pressure, temperature, and chemicals before you choose. Picking the right hose and checking it often stops leaks and breaks. Safety rules like SAE J517 and EN 853/856 help you make good choices. The right hose keeps everything safe and working well.

FAQ

What makes braided hoses better than regular hoses?

Braided hoses last longer and handle higher pressure. The braided layer protects the hose from cuts and damage. Many people choose them for safety and strength.

How can someone tell if a braided hose needs replacing?

Look for cracks, leaks, or rust. If the hose feels stiff or shows fraying, it may need replacing. Regular checks help prevent problems.

Can braided hoses be used outdoors?

Yes, many braided hoses work well outdoors. Stainless steel and synthetic braided hoses resist weather and sunlight. Always check the hose label for outdoor use.

Are all braided hoses safe for drinking water?

Not all braided hoses are safe for drinking water. Only hoses marked as “potable water safe” or “NSF certified” should be used for drinking water. Always read the label before use.